Salt production in the Mediterranean

The salt pans were born 3000 years ago with the Phoenicians and are characterized by a production that has remained substantially the same even 3000 years later. That of sea salt is truly a bio collection, an eco-sustainable collection within an eco-sustainable industrial activity, because 95% of the energy source is renewable. Sun and wind are the primary elements. The whole process is based on the evaporation of 90% of the sea water before reaching saturation.

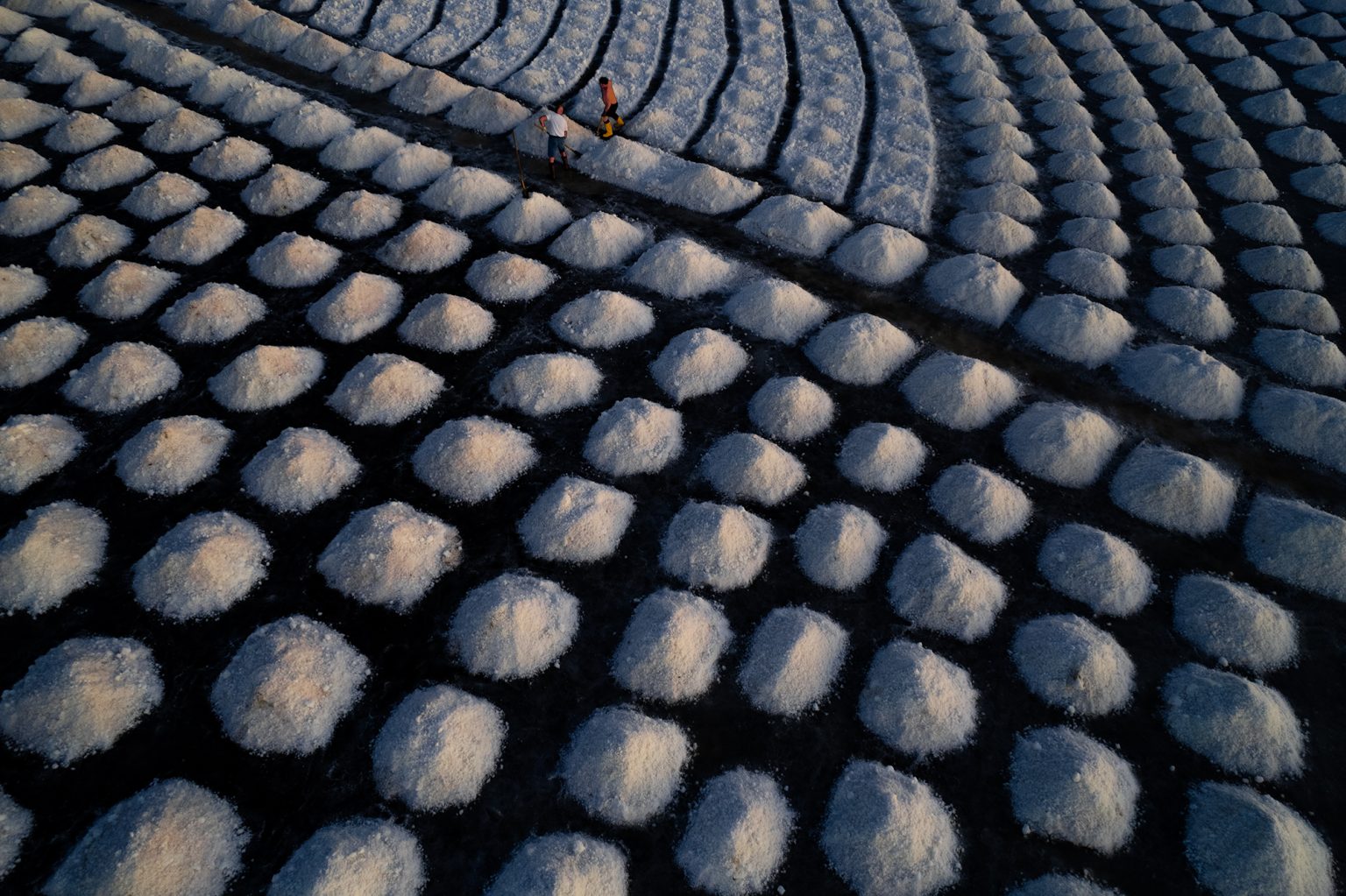

There are two types of industrial process linked to the extraction of salt. The manual one and the mechanical one. Both extraction systems have valid industrial and cultural motivations. The qualities of salt, which substantially do not differ as a product, begin to differ if it is collected manually or if it is done mechanically. Hand-harvested salt has specificities that machine-harvested salt loses. For this reason, hand-picked salt has all the characteristics to be a solid food grade. So salt for food consumption, albeit niche, without the need for any processing. This happens because the sodium chloride content is over 97% and, in addition, there are small quantities (0.3/0.4%) of magnesium salts and potassium salts, which give the salt thus collected a balance, especially from a gastronomic point of view, that other healthy people do not have. The salt collected by machine when it is in the tank is the same as that collected by hand because the crystallization is exactly the same but, both for how the bottom of the tanks are treated and for the different sensitivity that a machine has compared to man, it has a sodium chloride content below 97%. This requires subsequent processing to ensure that the salt reaches food grade.

The project is carried out within three Italian companies that differ in quality, size and type of product: The Apulian salt pans of Margherita di Savoia, the sicilian salt plants Italkali and Ettore Infersa.

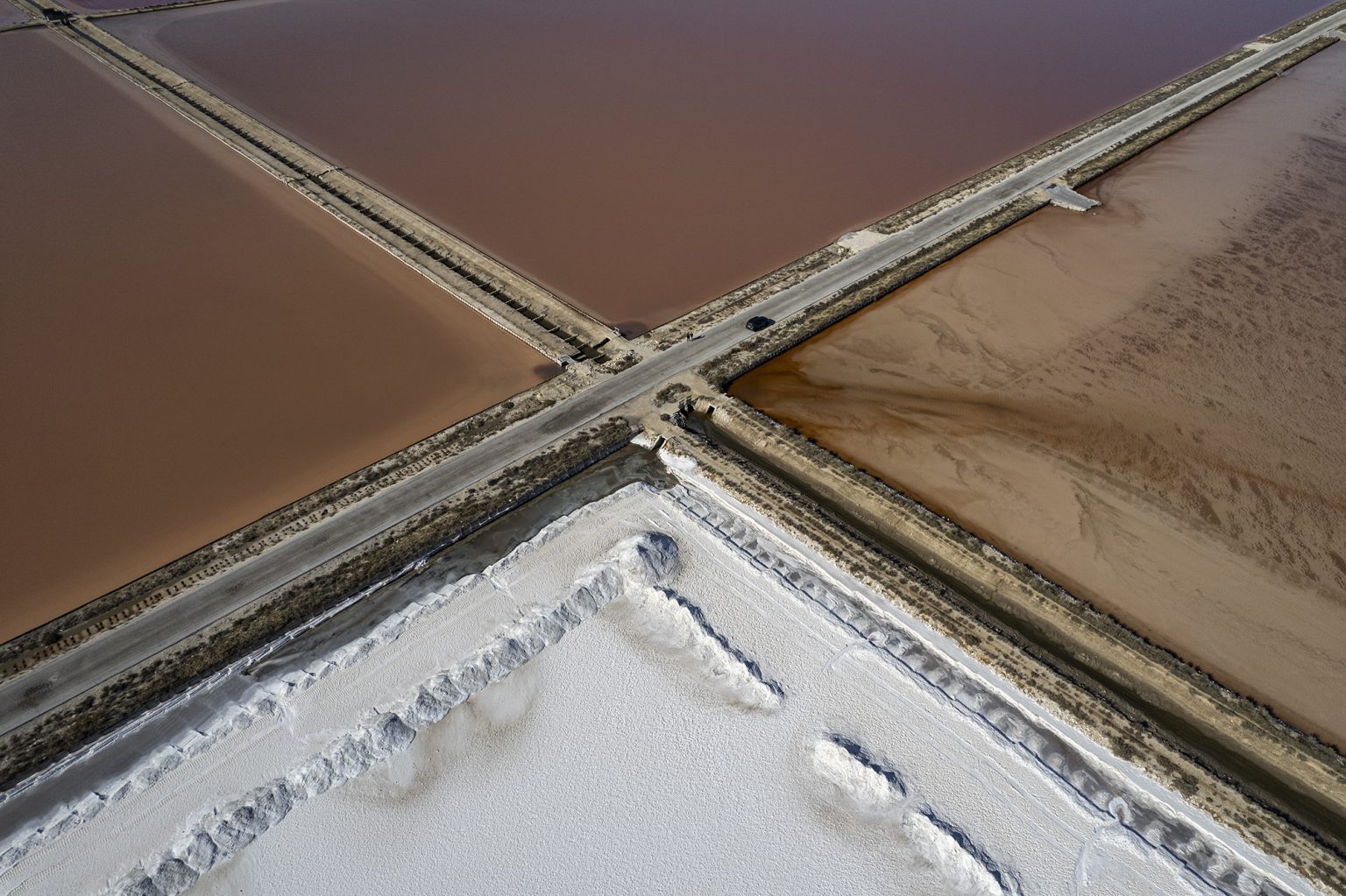

– The Apulian salt pans of Margherita di Savoia are the largest salt pans in Europe. The entire production area is considered a nature reserve due to the presence of numerous species of migratory birds. The interesting landscape aspect is that the salt marshes are separated from the sea by a strip of land. By production we can define it as the most important in the Mediterranean.

– Italkali – Società Italiana Sali Alcalini SpA – has been active on the market for over 40 years and has acquired the role of main player on the national market and important positions on the European market. The Sale di Sicilia brand is the best-selling iodized salt in Italy. Production takes place at multiple mining sites.

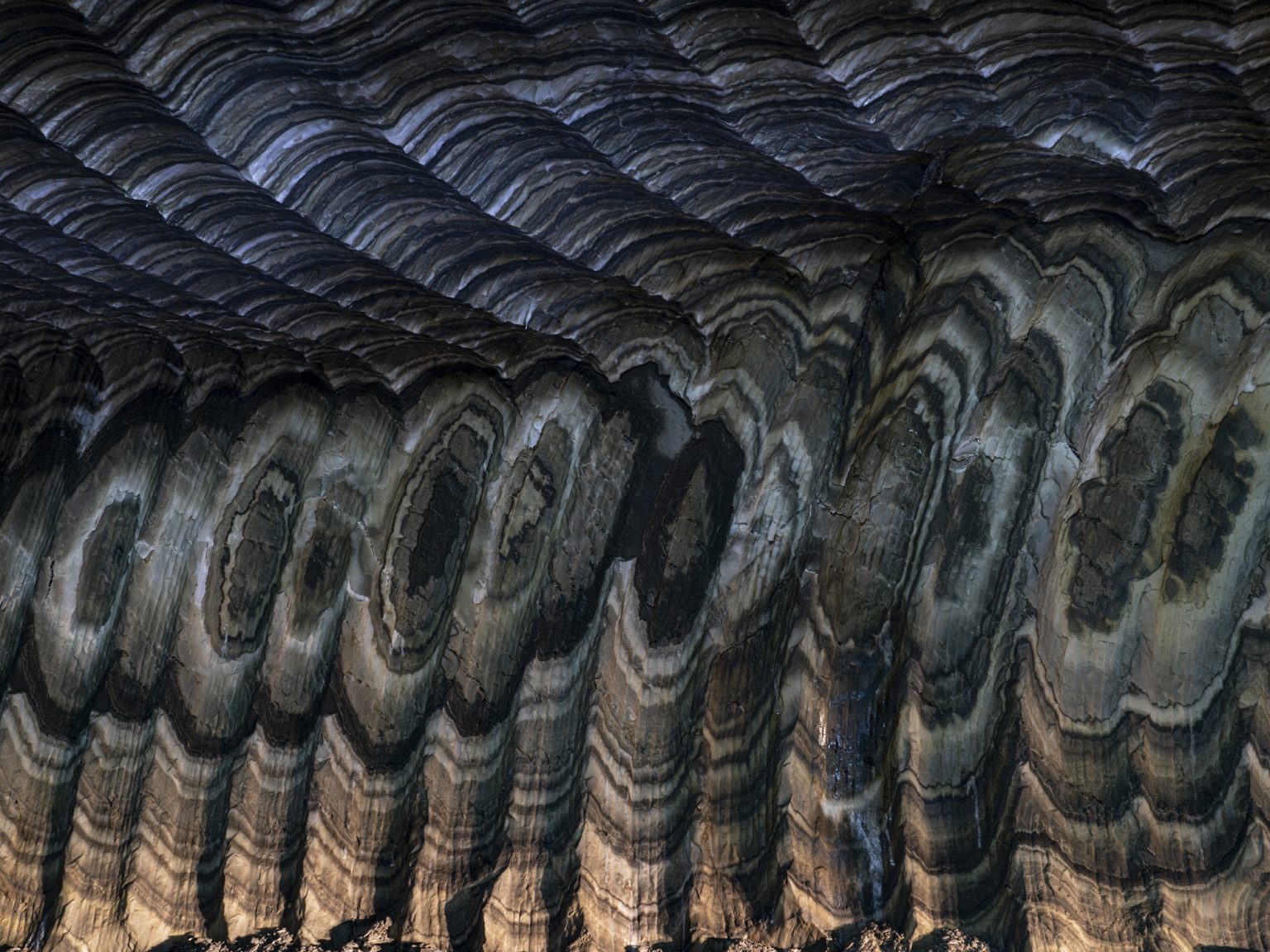

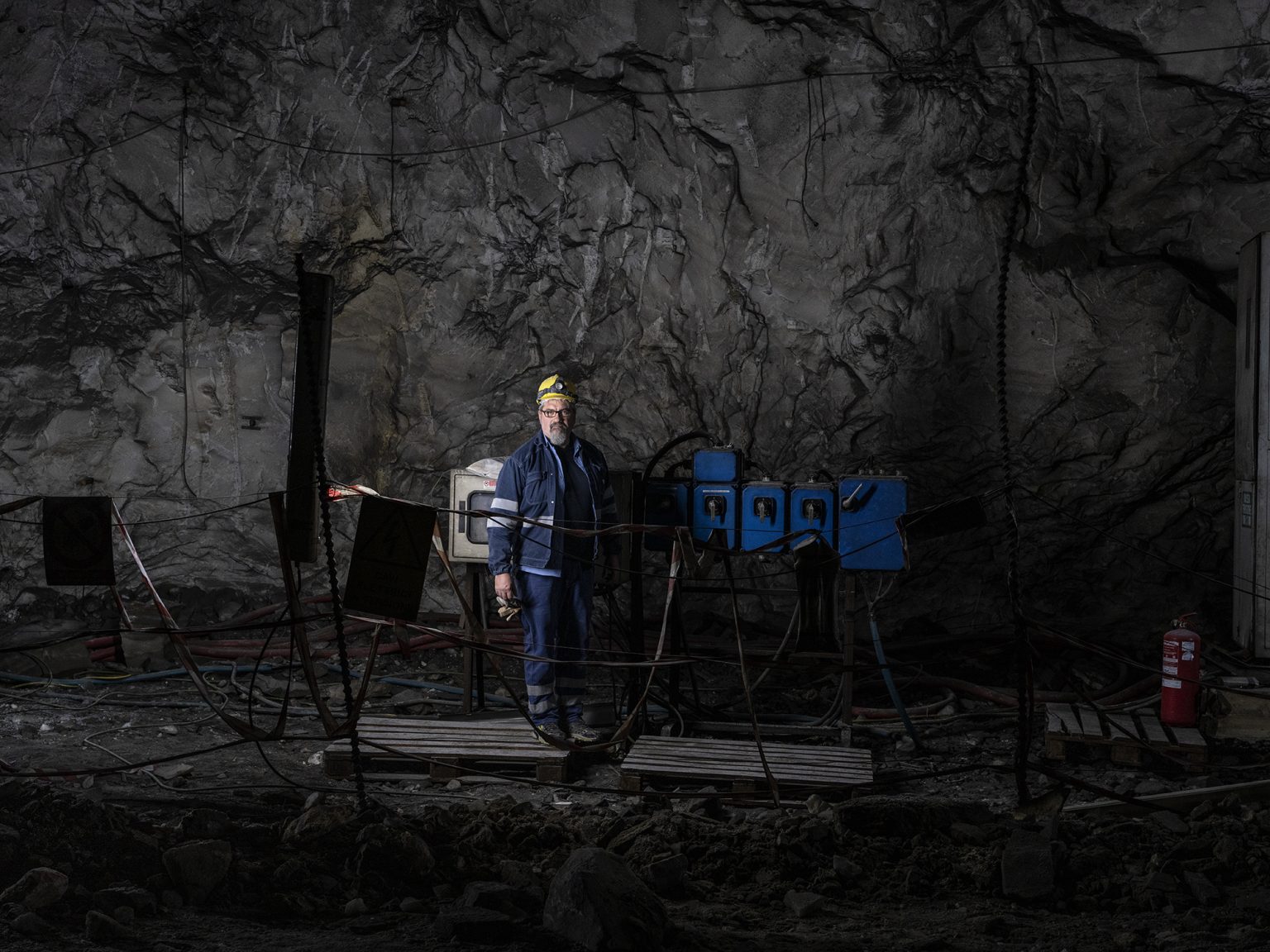

PETRALIA is one of the richest deposits in Europe: an enormous lens of salt enclosed in the heart of a mountain that rises up to 1,100 meters above sea level. Petralia salt has by nature an extraordinary purity which is shown in the particular brilliance of its crystals. The entire production chain takes place underground, from harvesting to packaging. Automated lines convey the product to the processing plants without any manipulation or chemical treatment. The most natural product on the market comes out packaged from the subsoil and sees the light again, after six million years, only when the package is opened.

REALMONTE overlooks the southern coast of Sicily and consists of a vast saline lens that develops between Porto Empedocle and Siculiana. For Realmonte, reserves of 70 million tons of rock salt and the presence of significant quantities of kainite (potassium minerals) are estimated. It currently produces over 1 million tons of salt a year, mainly for industrial use and as an antifreeze. The production capacity of Italkali is about 2 million tons of salt per year.

– The Saline Ettore Infersa company is based in Marsala where it produces about 110/120,000 tons of salt, in an area (Marsala and Trapani) which, overall, moves about 130/140 thousand tons of salt. The one harvested by hand is 2.5/3% of the total. To make manual harvesting easier, in the last year the company has activated night-time harvesting with work shifts that end at midnight each day. Alongside the production of salt, an initiative linked to niche tourism was born, which was given the name of “salt tourism”. A wellness program, inside the disused salt pans of the long island of the Marsala lagoon, in which you immerse yourself in tanks with different degrees of saline saturation of the water. An almost unique example on the international scene.In relation to the phenomena related to “climate change”, the salt pans are among the activities that can benefit from the increase in temperatures that favor the processes of evaporation and, therefore, the production of salt.